Product Upgrade Information - New Gear Leg for All 300mm Tunnel Thrusters

All ø300mm thruster models are now updated to the latest standard, providing more thrust, less noise, higher safety and faster installation.

Mechanical Changes

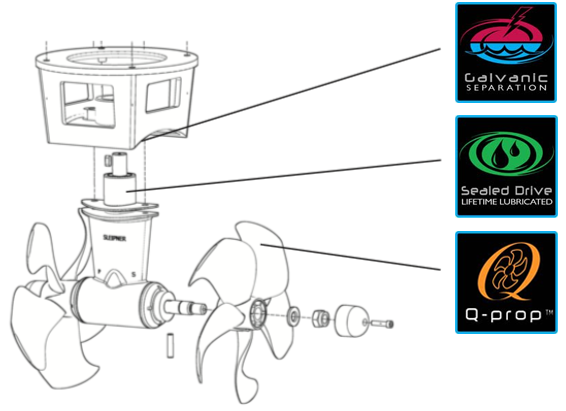

New gear leg

The gear leg has been redesigned to be slimmer and without bolt-ears to further improve the water flow and reduce the water turbulence resulting in better performance and efficiency. There are also some production oriented improvements internally to further safeguard the very high tolerance level in the machining and assembly processes of a Side-Power thruster.

Sealed gear leg

The gear leg now has ceramic axial shaft seals improving lifetime and durability, thereby allowing them to also be pre-filled with a special long life gear oil, not needing an over pressure oil reservoir. This simplifies the installation and service of these products.

Now with Q-prop™ 5 bladed propellers

The propriatary Q-prop™ design provide a significant noise reduction in most installations, while having a very high thrust efficiency as they are designed for the spesific thruster application they are used for. NEW on these larger composite propellers is that they are made in a new high-tech composite material that are less brittle than the material used on the smaller Q-prop™ products. They are simultanously rigid and true to the slim shape also under load, while still having a high resistance to extreme impact loads.

Galvanic insulation

The gear leg is now fully galvanically insulated from the rest of the thruster, so that any current leaks or short circuiting onto the parts inside the boat will not affect the underwater parts of the thruster. Mostly a benefit on electric thrusters, this is actually also a real benefit for hydraulic thrusters, as high-pressure oil hoses typically conduct through their metal brading causing risk of extra galvanic corrosion load in case of other "electric leaks" in anything connected to the hydraulic system.

Electrical Changes

Electric consumption

The increased thrust will result also in a slight increase in the current consumption - up approximately 3 to 5 %.

Implication On Installation In Boat

Mechanical

All build measurements and fitting routines remain the same as with the previous models, except that there is no longer a oil bottle and feed line to mount or a need to fill the gear leg with oil. This reduces the installation time saving valuable labour expense.

Electrical

While the electric consumption will increase slightly, few if any installations will require a change in cable size because the change is so small. If at all in doubt about your installation, please contact a Side-Power representative if needed to verify that you are using the correct cables and batteries.

Conclusion

For all boat builders using 300 mm tunnel thrusters today in their boats, the only practical implication they really need to consider is that the job of fitting the oil tank and filling the gear leg with oil is gone. However, due to parts compatibility we recommend that all boat builders change their internal part numbers for the thrusters or at least ensure that a proper change log is made for the boats with the new thruster models so to ensure that they know which model is on each boat.

Benefits Summary

- More Thrust

- Less Noise

- Less Inspection

- Quicker Installation

- Improved Corrosion Protection

Overview of Upgraded Models

| Discontinued Models | New Upgraded Models | Description |

|---|---|---|

| SP240TCI | SE250/300TC | DC on/off 250 kg thrust, 24 V |

| SEP240/300TC | SEP250/300TC | DC PRO 250 kg thrust, 24 V |

| SP285TCI | SE300/300TC | DC PRO 300 kg thrust, 48 V |

| SPP285/300TC | SEP300/300TC | DC PRO 300 kg thrust, 48 V |

| SRV285/300TC-48 | SRV300/300TC-48 | DC Retract, 300 kg thrust, 48 V |

| SRVP285/300TC-48 | SRVP300/300TC-48 | DC Retract PRO, 300 kg, 48 V |

| SP300HYD/xx | SH320/300TC-xx | Hydraulic, up to 320 kg thrust |

| SAC300-300/300-4 | SAC320/300-4 | AC PRO, 320 kg thrust, 400 V |

The new gear leg #20 0602 will replace gear leg #20 0600

The new motor bracket #20 0502 will replace motor bracket #20 0501

Backwards Compatibility

Older 300 mm tunnel thrusters can be upgraded in two ways:

-

Replaceing complete gear leg only. The old bracket can be used with the new gear leg. Just remove the external oil container as this is no longer needed.

Note: This will not make the model galvanic insulated due to the old motor bracket. -

Replacing complete gear leg and motor bracket. The thruster will be galvanic insulated.

For galvanic insulation in aluminium and steel tunnel installations, please contact your dealer for more information.

(Distributor asset: see document ID 4849 in mySite)

Note

The new 300 mm Q-prop™ is only compatible with the new gear leg #20 0602. In order to upgrade, the complete gear leg must be updated in older installations.